Preactor International

Preactor is an advanced planning and scheduling software company located in Chippenham UK. It has more than 10,000 implementations in 100 countries through multiple resellers worldwide. More than 50 support and product development engineers work in the parent office. (www.preactor.com)

Optimal Value started as a Preactor associate in 2000. We have worked as consultants for several similar APS products in the United States, Europe and Latin America across multiple industries.

Preactor acts as a digital traffic coordinator for factories: a central planning and scheduling system to automatically solve and control the traffic of materials and processes through to ensure that all customer orders are delivered on time.

Preactor is not an ERP, but it rather links with multiple in-house systems, ERPs or Excel to optimize and automate the end to end scheduling of multiple logistic processes in very short time windows. In a few minutes Preactor can process thousands of orders to balance materials, capacities and constraints and automatically solve all the factory productive activities while communicating plans to the executing areas.

Impact

Operational scheduling is very complex because events such as incoming orders, material and capacity shortages and machine breakdowns are constantly changing and it is necessary to evaluate multiple scenarios in very short windows of time: incoming orders, capacities, inventories, calendars and countless restrictions make finding the optimal solution difficult.

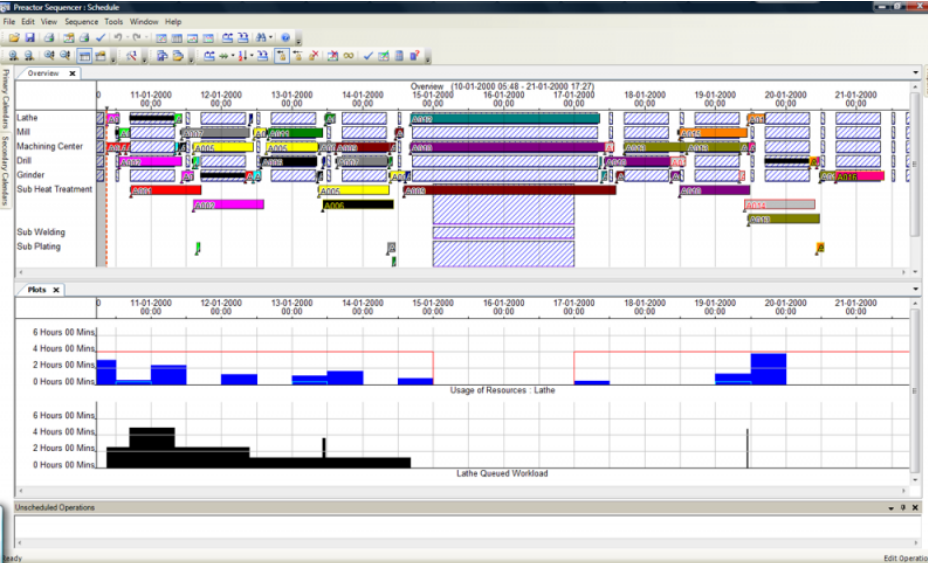

Preactor continuously monitors and rearranges these processes with sequential optimization algorithms, and allows the user to interact graphically with the resulting plans and indicators and interact directly with the suggested system solutions through a drag and drop gantt board.

The impact of the planning systems is very significant since they resolve and control the factory decisions automatically, unlike the ERPs that normally have very limited planning modules and require us to manually load the operational decisions.

Preactor is fully flexible allowing process configuration and algorithms to automate multiple decision flows and operational checkpoints which improve the use of resources of the company

- Reduction of delivery times

- Increased capacity utilization and reduced setups

- Speed to solve comprehensive plans in seconds

- Inventory reduction and cost optimization

- Reduction in capital expenditures

Siemens

Preactor was acquired in 2012 by Siemens as part of its industrial technology product portfolio.

Siemens is the leading sensor and infrastructure hardware supplier for machinery in factories worldwide, so there is high synergy between Siemens automation and sensor devices and Preactor scheduling: Siemens sensros monitor and feedback the production tasks that Preactor solves. (www.siemens.com)

Likewise, Siemens enables Preactor as the main axis of the concept of digital factory that precedes the high automation and digital interconnection of manufacturing worldwide. This initiative known as Industry 4.0 is currently booming in multiple industries.

Industries

Leading companies from all industrial sectors use Preactor to solve their processes and operations. Due to its high flexibility and adaptability Preactor APS is used in all these industries:

Transport - Aerospace - Plastics - Cosmetics - Food - Metals - Automotive - Pharmaceutical - Packaging - Printing - Materials - Electronics - Furniture - Textiles - Distribution - Metalworking - Machinery

Preactor Experience

Prior to Preactor, our consultants have international experience with leading companies in advanced planning systems. Blending multiple backgrounds and capabilities into a system such as Preactor resulted in an easy to use option with layers of experience in industry.

Optimal Value gathers expertise in the development of customized optimization mathematical systems with more than 100 manufacturing companies worldwide.

X3ntaur platform

As of 2016 Optimal Value begins the consolidation of the X3ntaur web platform as an innovative software project in SaaS mode, in order to meet the requirements of customers exploring to leverage cloud and mobile capabilities.

X3ntaur a toolset to leverage APS scheduling capability: MRP, floor control, KPIs and various communication tools with apps, sensors and automation scripts that are hosted on cloud servers directly connected to Preactor.

Work Team and Methodology

Optimal Value has several methodologies and work tools that have been refined over the years in multiple projects to expedite and streamline project performance. Through the use of digital documentation, e-learning and scheduling platforms, custom development and training programs are developed for each client, tailored and validated based on their needs.

Our staff is rigorously selected and trained in various disciplines of process engineering and programming with multiple languages and internal tools, which allows for flexible solution management for our customers environment.

Previous Results

- 100% improvement in solution time and planning calculations

- 25% improvement for on time deliveries

- 25% reduction in delivery lead time

- 25% improvement in inventory and utilization

- Long-lasting custom system in continuous use

Some Companies Served

Tupperware - Crocs - Grupo Modelo - Polykon Plastics - CCL Container - CCL Label - CCL Autoparts - CCL Electronics - CCL Film Rolls - Jafra Cosmetics - Eli Lilly - Grossman Labs - Central Bank - Maxim Semiconductor - Textron Autoparts - ICoyo Print - Uquifa Pharma - Siemens Switches - Siemens Engines - Siemens Power Grids - Galas Packaging - Maxion Inmagusa Autoparts - Enkador Textiles - Safran Aeroespace - Engranes Engramex - Libbey Glass - Alcan Packaging